LIGHT WEIGHT DESIGN – SHAPE AND WEIGHT OPTIMIZATION

Dassault Systèmes has created a new work environment within the 3DEXPERIENCE platform, in which topological optimization of model shapes (using CATIA applications for organic shapes) and design simulations (with the SIMULIA tool) are combined together. The solution is called Functional Generative Design and means the unification of modeling, simulation and optimization in a single environment.

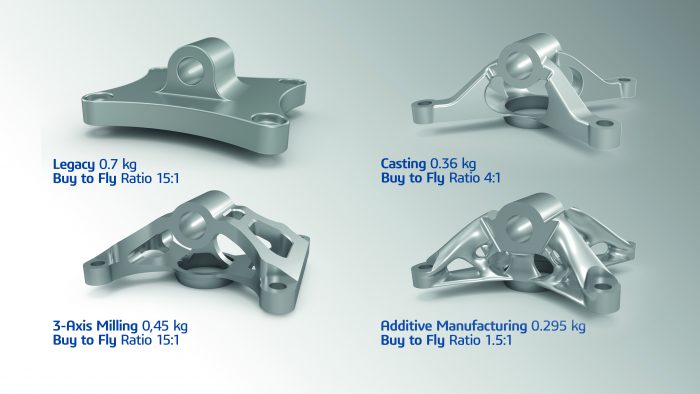

Designers can now automatically generate optimized conceptual parts at the push of a single button from the functional specification. The user can then change specifications and quickly create multiple concepts for comparison. It is now possible to create organic shapes that could not be imagined using a conventional approach and so drastically reduce the weight of the proposed part. This allows the user to take advantage of the flexibility of additive manufacturing, but also the possibilities of traditional manufacturing processes.

THE SOLUTION’S ADVANTAGES:

-

- Shape optimization in a single environment

- Unified platform for design, simulation and manufacturing technology

- Designers save time: optimization in Light Weight Design takes only several tens of minutes

- Intuitive procedures

- Fast prototyping

- Saves weight – 30-70% depending on manufacturing technology

- Light Weight Design is suitable for any manufacturing technology